Procolored F13 Panda L1800 DTF printer review

Specification

type: Inkjet DTF printer

Function: Print on transfer film

Connectivity: Ethernet, USB

Data storage slot: No

Print speed: 8 feet/hour

Paper capacity: 33cm roll

Print quality: 1,400×1,400dpi

Apple AirPrint: No

Consumables include: 6 x 250ml ink bottles

Dimensions/weight: 765 x 385 x 395 mm (WxDxH)/18kg

The Procolored F13 Panda L1800 is a dedicated DTF printer aimed at hobbyists and entrepreneurs looking for medium-sized custom garments. It’s an easy-to-use, affordable, consumer-friendly printer that also features a wide format and high ink capacity that will interest established print shops producing up to 50 pieces per day. But first, what is a DTF printer?

DTF (direct to film) is a process of printing specially formulated liquid ink onto plastic film for transfer to a fabric surface using a heat press. It differs from sublimation printing, in which dry ink on the transfer paper is sublimated by heat into a gas that can penetrate the fibers of some textiles and other materials (for more on this, I reviewed The best dye-sublimation printer It’s there now). Therefore, DTF is less durable for surface printing, but it is also less picky about fabrics, and there is no problem printing on black cloth because it adds white ink to the usual CMYK four colors.

Procolored F13 Panda L1800 uses Epson An inkjet printhead sprays ink droplets onto a 13-inch (33-cm) roll of transfer film. This means you can print tabloids or high-resolution graphics up to one meter wide in A3 size. This semi-professional printer costs around $3,000/£2,400 and includes the Windows software, a set of 250ml ink, a roll of plastic film and a bag of adhesive powder (necessary to cure the transfer material). But if you also want the tabloid-sized Procolored Panda oven I used for this test, then the all-inclusive price is around $3,400/£2,800. I also added a Panda heat press, costing around $469/£360, to complete my Procolored line.

Procolored F13 Panda L1800: Design and Build

The Procolored Panda L1800 Printer feels like a professional tool because of its sturdy, all-metal construction, while the playful Panda logo makes it look more like a consumer product. Either way, the design and build quality are excellent. The various metal hinges and flaps are built to last, and the equally sturdy roll holder and cutter are bolted on with satisfying precision. The design is quite compact compared to other wide-format fabric printers, while still being large enough to accommodate a 13-inch (33-cm) roll of transfer film for printing on tabloid/A3-width paper up to one meter long. The bottle holder on the right also has plenty of room for ink. Each of the five bottles holds 250ml of DTF ink. The whole thing weighs less than 40 pounds (18 kilograms).

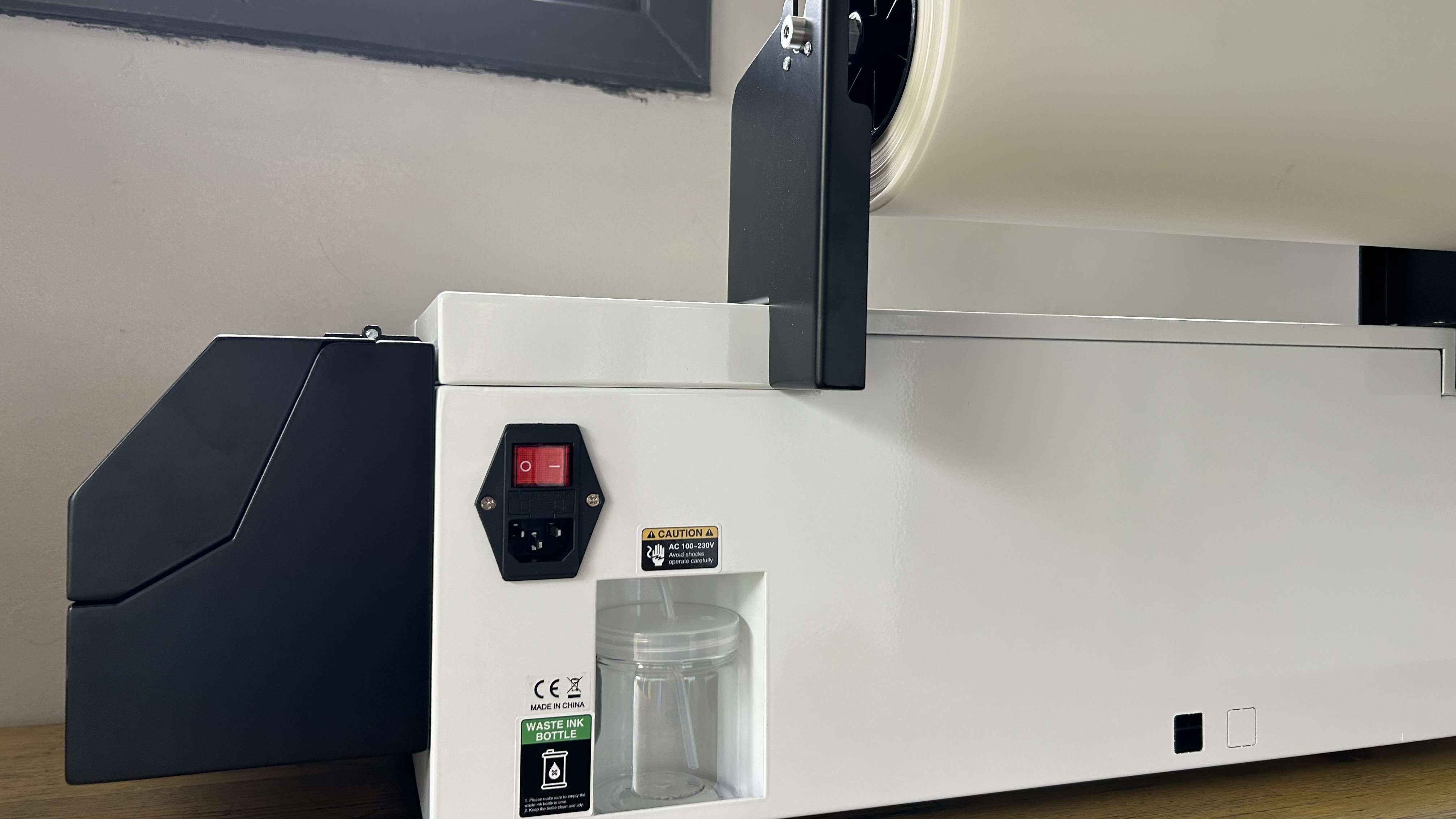

Inside the steel body, long tubes of clear plastic look more like science projects than polished products, but it all works well. Unfortunately, it doesn’t have a touchscreen interface, just an LED display that shows operating temperature and a few large button controls.

The included Procolored Panda Oven is a simple steel device used to heat the printed film to 120 degrees to cure the DTF ink, ready for transfer. It will take tabloid-sized paper, so the footprint is similar to that of a printer, and it has a flat surface that makes it easy to lay out and check your work. Likewise, the metal construction feels sturdy enough to withstand life in a busy print shop.

Procolored F13 Panda L1800: Features and Specifications

The Procolored F13 Panda Kit includes everything you need to print from PC to fabric via film transfer. The L1800 printer itself can print onto a 13-inch (33 cm) roll of plastic film, which can then be cut to length (up to one meter) using the included cutter attachment. You can also feed regular letter paper or small newspapers when running the nozzle check, but there is no input tray.

It uses inkjet technology to apply specially formulated DTF ink to polyethylene terephthalate (PET) film. The quoted print speed is a bit longer than the eight feet per hour for a typical photo printer. I find that letter-size designs take 5 to 10 minutes, and tabloids take 10 to 20 minutes. Procolored recommends production of 20 to 50 pieces per day, which is suitable for medium-sized shirt companies.

One advantage of DTF printing compared to dye-sublimation printing is that it adds white ink to four CMYK colors, allowing printing on black fabrics. White DTF ink clogs easily, but this printer avoids printhead clogging by circulating white ink, even when not in use. The only drawback is that DTF consumes more energy than sublimation.

Procolored F13 Panda L1800: Setup

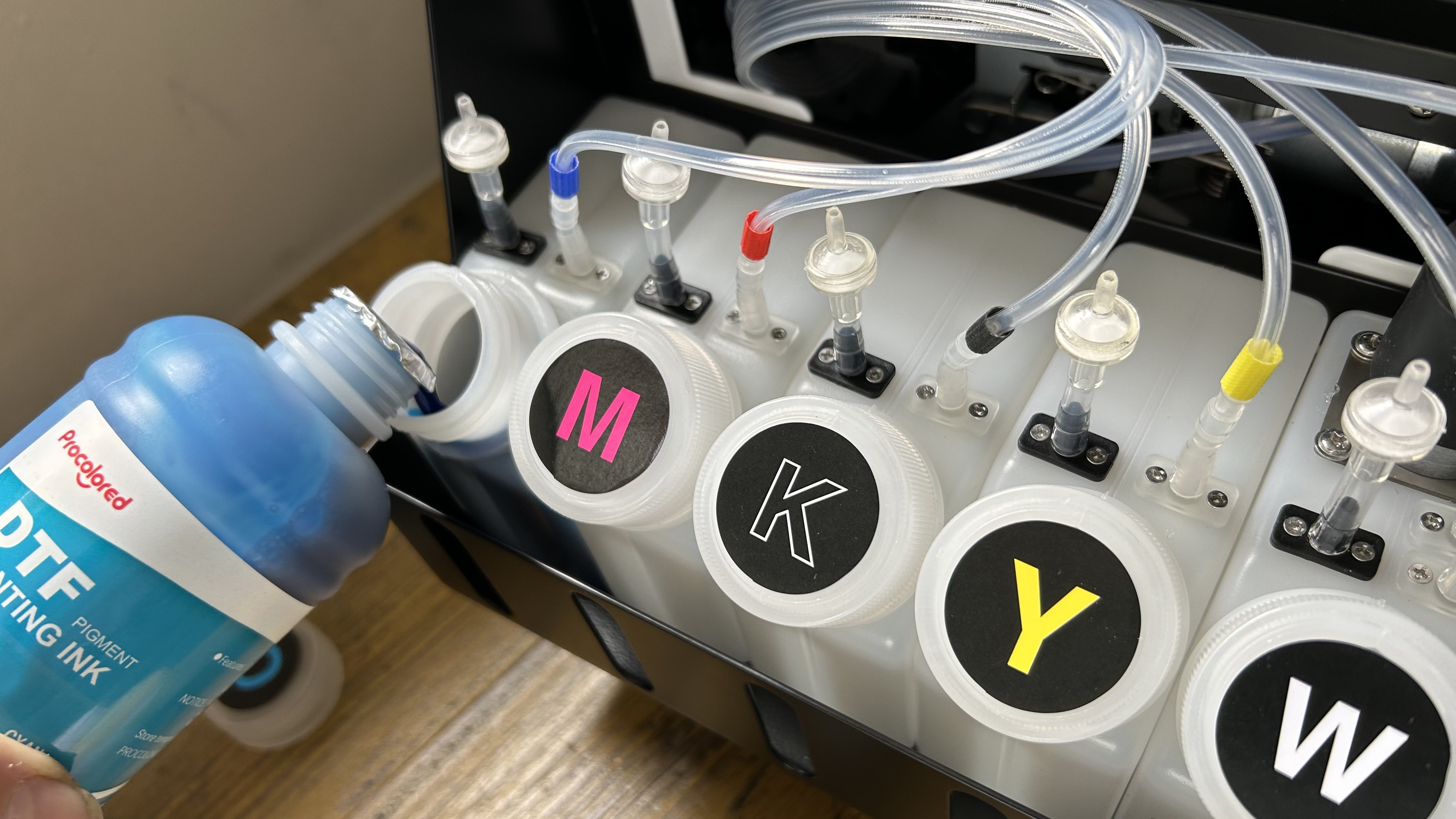

If all goes according to plan, setting up the Procolored L1800 printer from scratch takes about half an hour. The roller assembly needs to be screwed to the machine, so you’ll need a screwdriver, but it’s pretty intuitive and you probably won’t need to refer to the online instructions. The knives are clamped in a logical-like manner. Loading the ink requires more care, pouring the five 500ml bottles into the correct five 250ml ink bottles without spilling any ink. I spilled a few drops, but the water-based ink cleans up easily. Each color must be drawn into the print head through the long rubber tube using the included syringe. Once the film and ink are loaded, the printer can be turned on and brought to operating temperature. DTF printing requires a temperature range of 20°C to 25°C (68°F to 77°F) to maintain stable ink viscosity.

So far, everything is simple. However, I had real trouble installing the necessary Procolored RIP software and printer driver. The first hurdle is finding a Windows PC with adequate USB input. Since there’s no built-in Wi-Fi, you’ll need to run a cable to the printer and provide a second USB port for the dongle, which must remain plugged in while the software is running. Procolored software and drivers are delivered via USB stick, so the third USB port is very useful. Even so, it took me a lot of time and help from the patient Procolored Chinese engineers before I started printing. Maybe my issues were due to user error, so I don’t want to disappoint anyone at this stage, but I do think the software side needs improvement, and you’ll need some Windows OS experience to install it. Procolored is still developing Mac software for this product.

Procolored F13 Panda L1800: Operation

Once you’re up and running, printing t-shirts is fairly easy and fun, although I have to admit to making a lot of mistakes and typographical errors along the way. First, open the Procolored RIP software, resize the canvas to fit your shirt size and import your design. When you’re done working on it Photoshop– Styling software, click RIP. If this were a consumer product, the button would be labeled “Print”, but technically your image is undergoing raster image processing to create a bitmap that the printer can read and print.

After a few minutes of printing, you’ll have a warm, moist version of your design on film that can be sliced using the integrated cutter. The ink smudges easily before it cures, so you need to be careful when covering it with the adhesive powder (included). After pouring the excess powder back into the bag, place the film in an oven at 120 degrees. When your transfer material is cured and ready to be removed, the Procolored oven will automatically raise to this temperature and sound an alarm after 180 seconds. It’s still a little sticky at this point, so it’s best to go straight to the pressing stage. After ironing your regular clothes and waiting for the heat press, place the transfer paper on top and start the heat press. Procolored’s heat press also defaults to the correct temperature and automatically turns back on after 45 seconds. Take off the T-shirt, wait a few minutes for it to cool, then peel off the film so the pattern is permanently affixed to the fabric.

Procolored F13 Panda L1800: Performance

If you want to print detailed graphics onto fabric with a high-quality surface, you should definitely try the Procolored F13 Panda set. I printed various images on various textiles to test its performance, and I was always impressed with the results. Five DTF inks are intensely pigmented and combine to create vivid prints and very accurate color on film that retain that boldness when cured and pressed onto garments. What’s more, the color seems to stay the same after multiple washes. In tests, I used shirts made from 100% organic cotton, a polyester blend, and bags made from 100% polyester, and found the initial clean transfer to be the same in each case. However, parts that are best suited for a heat press are the easiest to transfer. Items larger than A4 size heat press must be pressed several times in stages, the design will stretch and cannot be transferred.

I chose high-resolution test images, and the printer’s 1,400 x 1,400 dpi resolution was able to turn them into crisp graphics that stayed sharp on the fabric. DTF has a resolution advantage over dye-sublimation, and thanks to the addition of white ink, such DTF printers can print on dark fabrics without compromising quality. Sublimation only works on light-colored fabrics, preferably white. The downside is that DTF requires more equipment for the extra curing stage, but if you can afford it and accommodate a curing oven, water-based DTF inks are generally cheaper than sublimation inks.

Procolored F13 Panda L1800: Supplies

The Procolored F13 Panda package contains a 500g bag of gel powder, a roll of PET film, a printhead cleaning kit and an initial set of DTF ink (six 250ml bottles). That is, one bottle each for CMYK and two bottles for white, with the latter being used more often. Procolored says that six bottles of 500 ml (CMYKWW) ink can print approximately 800 A3 (13″ x 16″) size images, or 1,600 A4 images. Prices for so many Procoored inks are around $300/£200, which seems reasonable, although there’s nothing stopping you from buying third-party inks, which I’ve seen for less than $100. In other words, DTF pigment ink is affordable, and the consumables cost to print a T-shirt is well under $1 per piece.

Procolored F13 Panda L1800: Maintenance

DTF printers require more maintenance than regular inkjet printers, but luckily, the Procolored F13 Panda L1800 automatically cleans its own printhead every 10 hours when it’s on, consuming about 1 ml of ink per day. However, if you leave the printer for more than 7 days, it is recommended that you empty the ink.

Procolored F13 Panda L1800: Final Verdict

There’s a lot to like about the Procolored F13 Panda L1800. The design is logical and attractive, and the steel construction feels durable. It can print large designs on 13-inch paper rolls and cut them with an integrated paper cutter. I had difficulty using the Procolored RIP software initially, but once you know what you’re doing, you can produce enough printed garments every day to satisfy the needs of a small business. And the print quality is very good. By mixing five DTF inks (CMYKW) together, it creates vivid and detailed graphics that can be faithfully transferred to almost any type of fabric.

There is room for improvement. I found the Windows software to be unintuitive and only worked when the dongle was plugged in. Procolored assured me that the Mac software was coming soon. Despite some clever automatic ink management, the printhead is a bit prone to clogging, and I’d like to see Wi-Fi and a reset button in the next version. In many cases the printer wouldn’t connect to my computer, or it ran out of ink, or the paper slipped, so it wasn’t perfect. That said, this is a very good DTF printer at a reasonable price.

For more devices we reviewed Best Small Business Printers and The best home printer.